Requesting a quote

Are you interested in our hygienic sealing rings?

Then contact us or request a free quote here!

We will then contact you within 24 hours

Combifit T-rings, Tri-clamp rings and Flat rings

Combifit Metaalbewerking B.V. supplies hygienic sealing rings that can be used in couplings that comply with ISO-2852, ISO-2853, DIN, IDF Unions - BS 4825 (parts 3 and 4) and ASA standards. The couplings are applicable in hygienic and aseptic processes and lend themselves to "cleaning- or steam-in-place" (CIP or SIP) cleaning.

The design

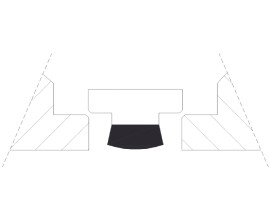

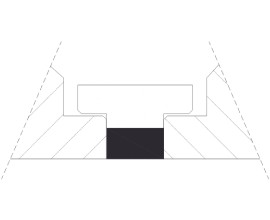

The T-profile of the ring automatically aligns the connecting coupling parts, and the solid stainless steel outer ring ensures that the Combifit T-ring snaps into place and is easily removed.

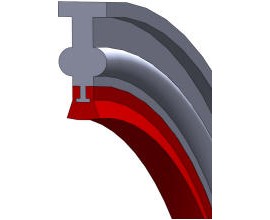

During tightening of the coupling, the rubber inner ring can only be compressed 14%, after which the stop of metal to metal follows. So besides the rubber seal, there is also a metal to metal seal so a damaged ring can never cause a serious leakage. The Combifit T-ring, Flat ring and Tri-Clamp ring have a longer life and thus a longer service life.

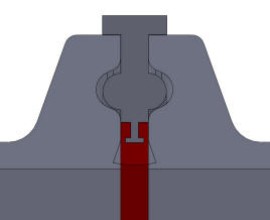

male part Combifit T-seal liner

The inside is tight without liquid remains

Tri-Clamp compressed

Stainless steel outer ring

Like single rubber seals, the Combifit hygienic seal rings cannot be blown out of its seat by the process pressure. The rubber inner ring is enclosed in the installed coupling by metal walls of stainless steel. For this reason, it is possible to apply (fragile) silicone rubber, which is important when using high temperatures, for example when sterilizing the installation at 140-150°C. The Combifit T-ring, size 1½", underwent a pressure test of 250 bar and was found to be leak-proof and tight.

The Combifit T-ring can be installed in all existing ISO-2852, ISO-2853, DIN, IDF Unions - BS 4825 (parts 3 and 4) and ASA systems.

Our Combifit T-ring has been subjected (installed) to a severe bacteria test, then flushed into the pipe and come out completely clean. The rubber grades EPDM, Silicone and FKM (grade 1) are FDA, EC 1035/2004 compliant and thus meet current food industry requirements.

Commercial aspects

The use of our rings and quick installation saves time. In addition, sterilization times are reduced because cleaning can be done at higher temperatures. On top of that, maintenance and downtime costs are saved. Enough reasons why the Combifit T-rings, tri-clamp - and flat rings have been used for over 20 years with excellent results by, among others:

Rubber specifications

Rubber technical data sheets are available upon request but are also sent with each initial order. They meet at least the following requirements:

FDA 177.2600 (incl E&F) , EC 1935/2004.

In addition, we provide the rings with coding so we can trace and return the rings to customer, production date, rubber batch, and rubber type at all times.

CIP or SIP cleaning with different cleaning agents, duration of contact with the cleaning agent or base materials, temperature, pressure of the production process or cleaning procedures, frequency and sequence of cleaning all affect the quality of the rubber and thus the life of the ring.

Therefore, we cannot advise which CIP/SIP cleaning is suitable for which rubber and how many cleaning cycles the ring can handle before it needs to be replaced. At all times the choice for the specific rubber should be presented to a CIP/SIP specialist and tested in practice regarding its durability. This is because of the number of variables that affect rubber quality and it has been found that theory and practice do not always match.

Technical Specifications

If an item does not appear in our standard program, please contact us. In fact, we can also make custom rings. For this we charge a one-time fee for making the molds.

We may be able to meet your needs.